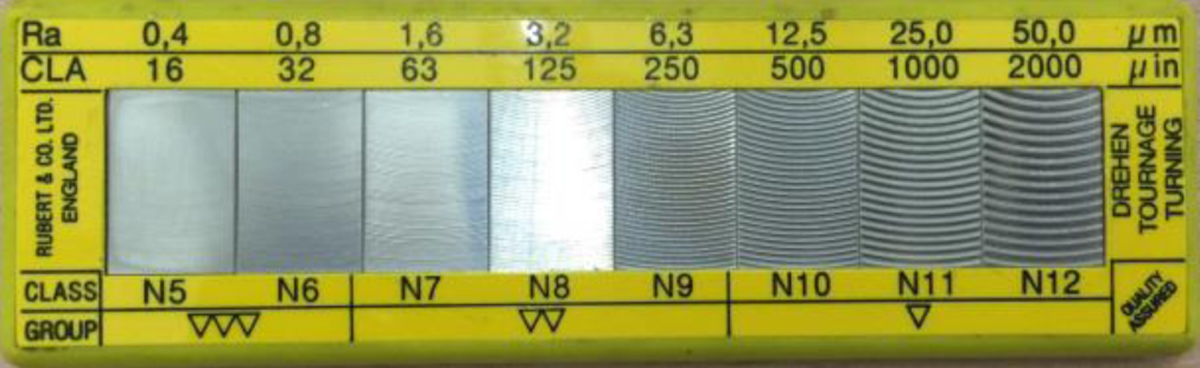

Surface Finishes Chart For CNC Machining: The Ultimate Guide - Xin Tian Jian Precision Mfg Ltd 2023 September

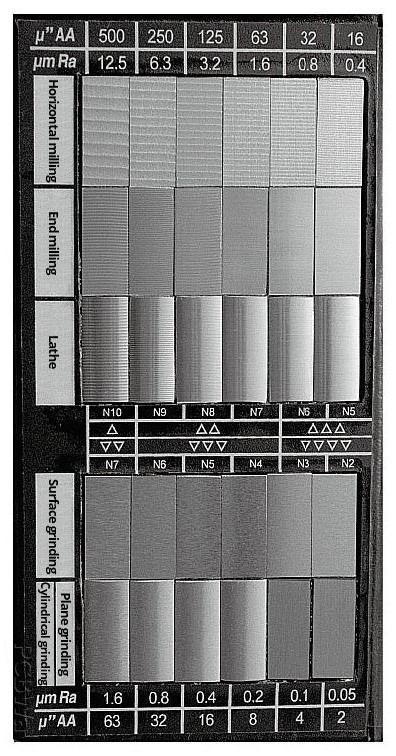

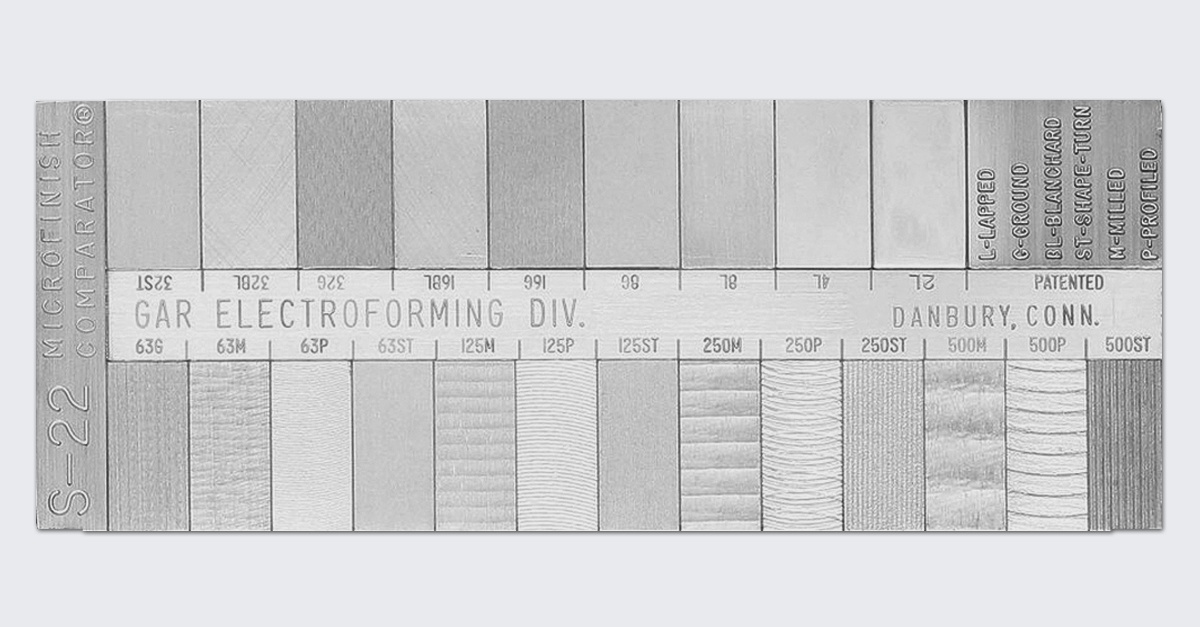

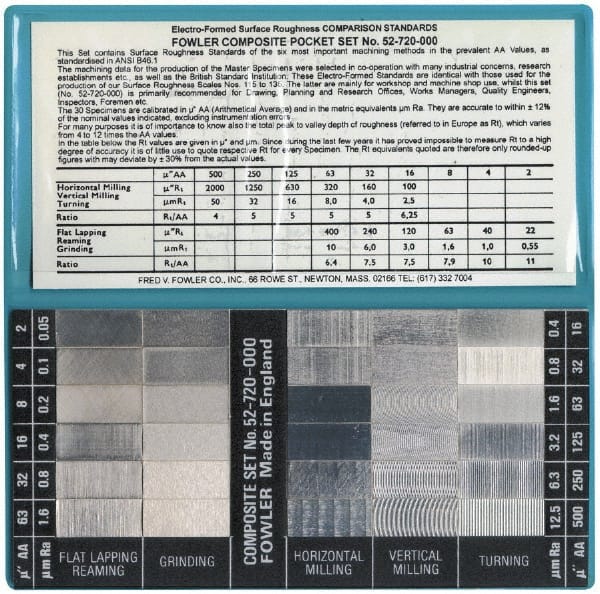

Fowler - 2 to 492.126 micro Inch Surface Finish, Nickel, Surface Finish Comparator - 99726937 - MSC Industrial Supply

Average surface roughness evaluation using 3-source photometric stereo technique | International Journal of Metrology and Quality Engineering (IJMQE)

Alternative Surface Roughness Measurement Technique for Inaccessible Surfaces of Jet Engine Parts Using the Rubber Silicon Replica Method | SpringerLink

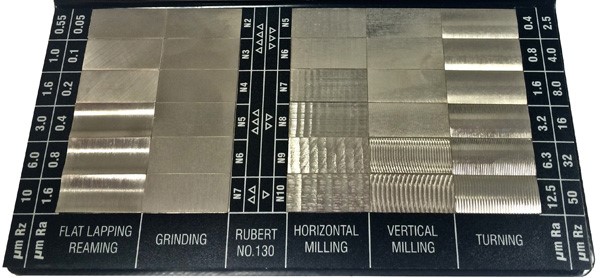

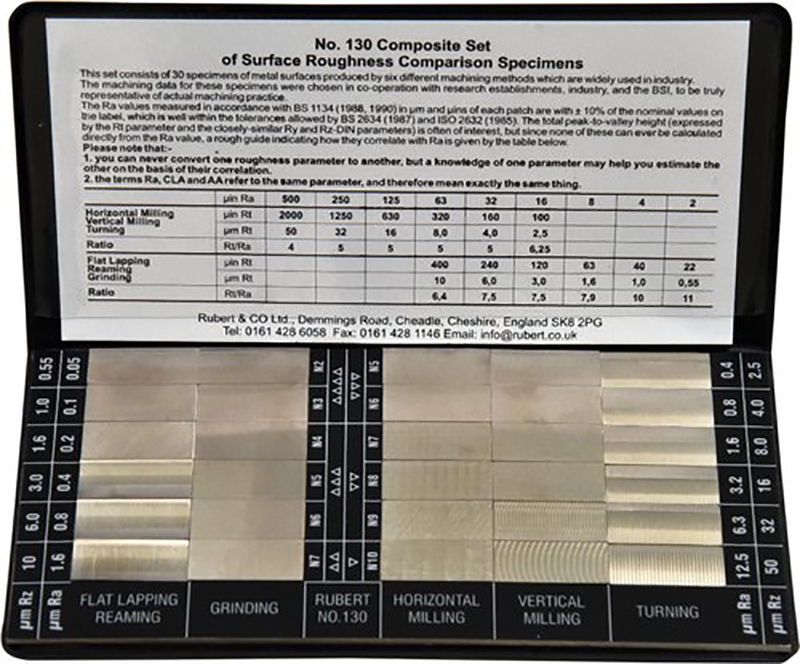

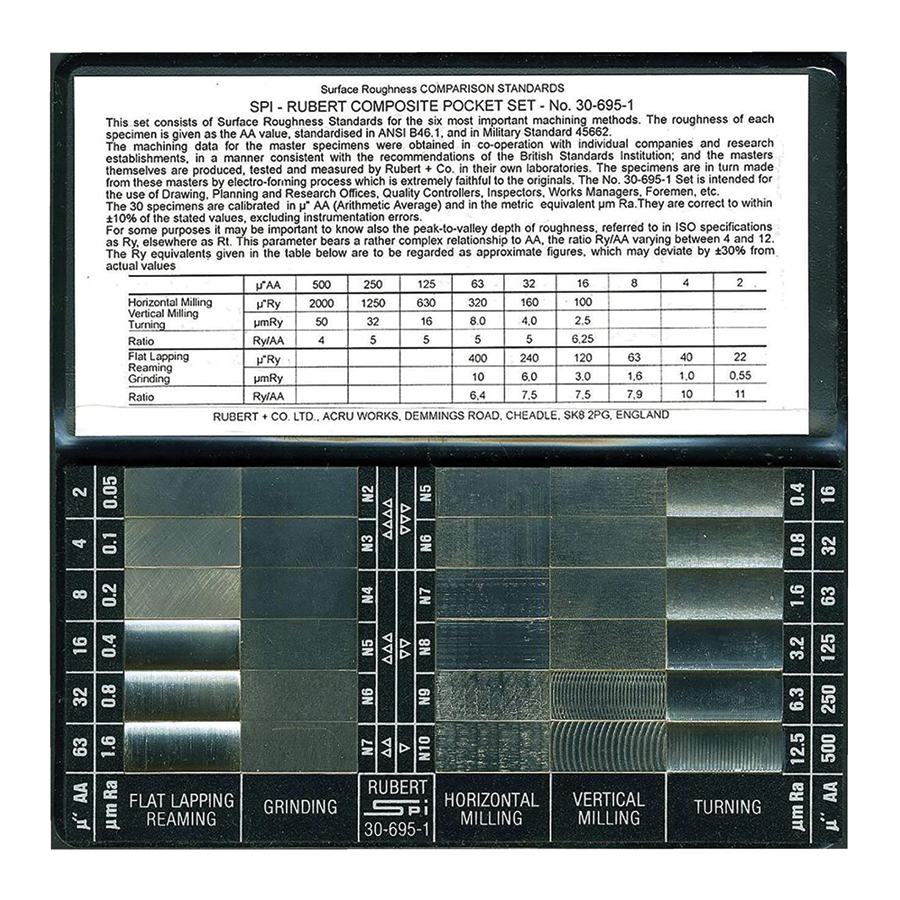

Fowler 52-720-000-0 Surface Finish Comparator Set, 30 Specimens: Surface Roughness Comparators: Amazon.com: Industrial & Scientific

Is this an acceptable surface finish for a face mill? Trying to see if I got my feeds and speeds right for roughing on a Coromill 745. : r/Machinists

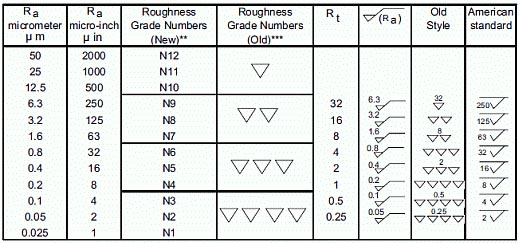

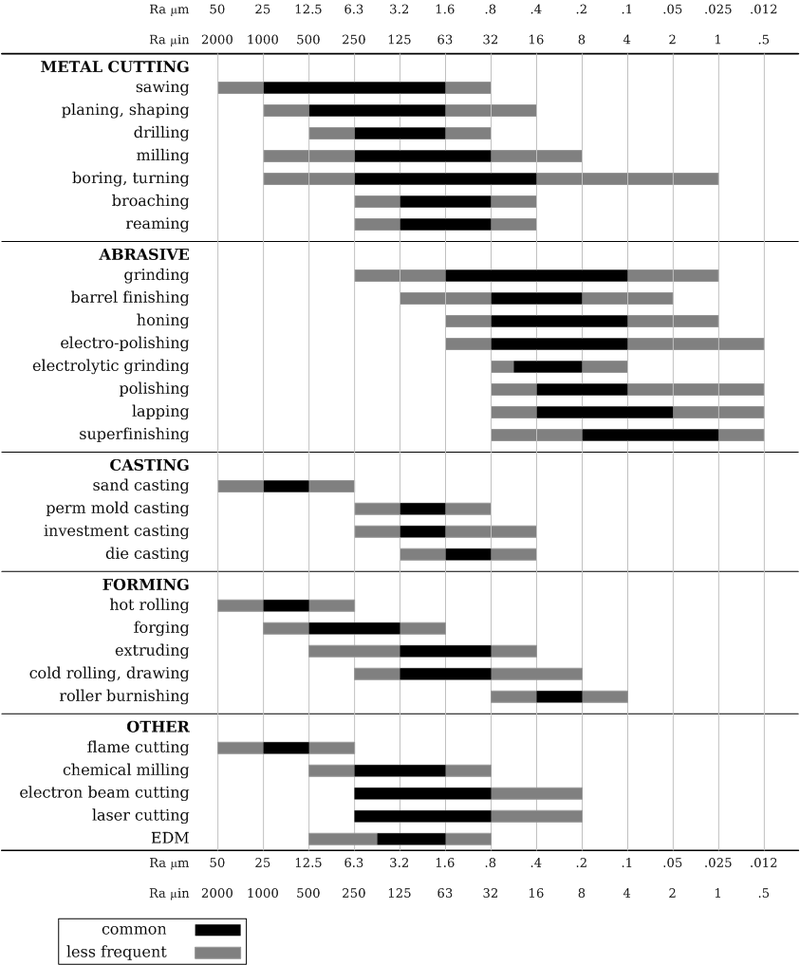

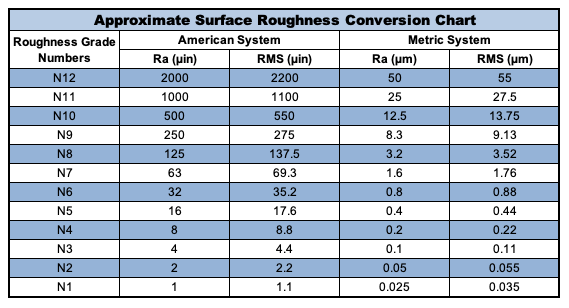

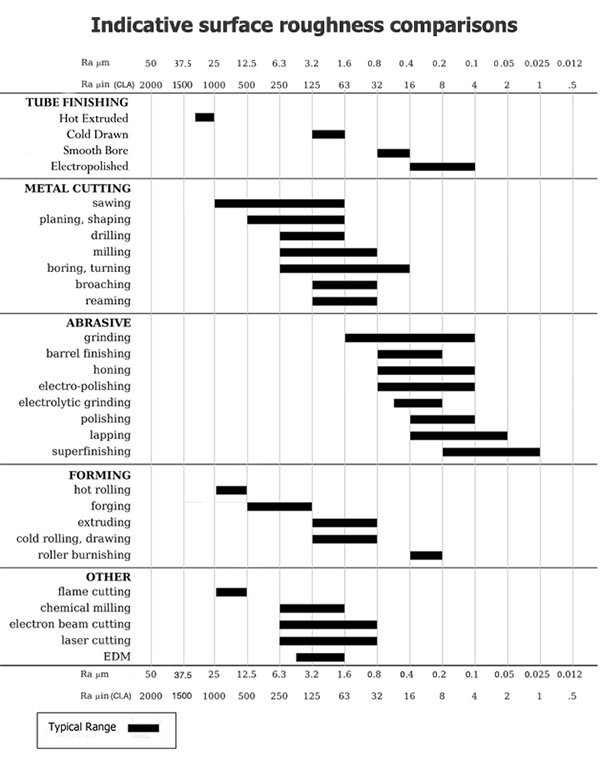

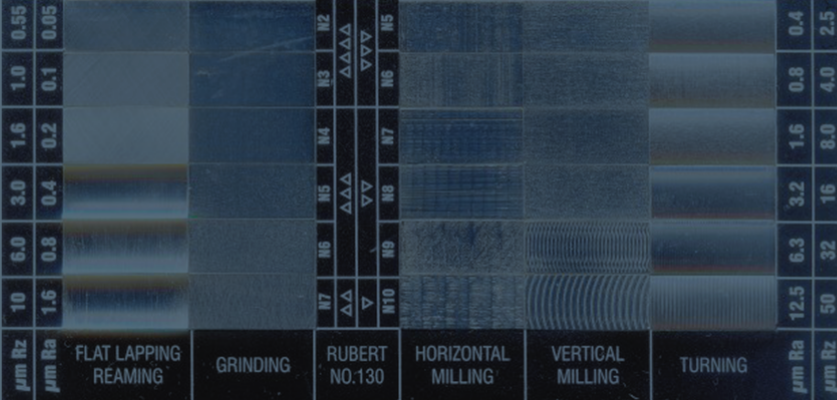

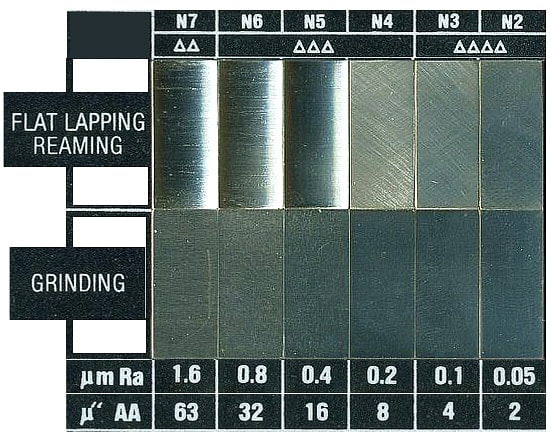

How to deal with the surface finish for your precision CNC machine parts. | CNC Precision Machining Service